3D Printing

This manufacturing technology allows us to take 3D digital models and bring them into the real world! The parts are produced layer by layer in variety of materials and methods. This allows us to create prototypes, props, models, miniatures and more without the considerations of tooling or molding. Resulting in a faster workflow with more freedom of design.

FDM Printing

FDM ( Fused Desposition Modeling). These parts are created layer by layer extruding thermoplastics to form the final part. Using common thermoplastics such as PLA, PETG, ABS, Nylon, TPU and more, allows for high strength parts with a variety of properties. These parts tend to be of high strength, but have a distinct texture of build lines on the printed part. These parts can be sanded, painted, plated and finished to a higher quality depending on application. The most affordable method of 3D print is still incredibly robust and able to produce strong, large, and reasonably detailed parts.

MATERIALS AVAILABLE: PLA, ABS, PETG, ABS, NYLON, TPU

RESOLUTION: 1mm to 0.1mm (imperial units)

We are able produce single parts as large as 2 ft x 2 ft (metric). And are able to create much larger parts through sub-assemblies! Feel free to inquire for more information.

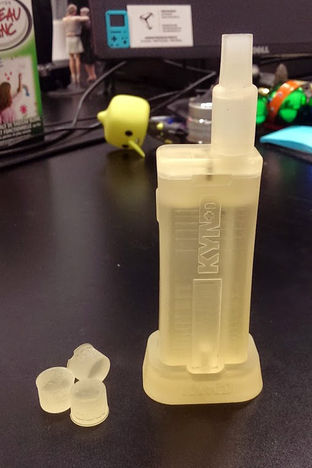

DLP/SLA/SLS/EXOTIC

PRINTING

We utilize DLP (Projected UV Image) printing in house. This methods creates incredibly high resolution parts suitable for fine molding applications. Typically used to fine small parts, such as film, jewelry, dentistry, electronic enclosures, artist application, miniatures, sculpture, mold and model making.

MATERIAL: UV Cured Arylic Resin (Clear, Gray, Black, White, more), Castable Wax

RESOLUTION: 0.5 mm to 0.02 mm (imperial)

Through our relationship with manufacturers in Canada, we offer reliable 3rd party services for SLS (Nylon and Metal), SLA Acrylic Resin (2ft x 2ft), Multimaterial Objet Printing (Full Color Plastic, Variable Flex and Clarity Materials), Full Color Powder Print (Full Color Sandstone Print).